White Metal Alloys

Pewter

Featuring Lead Free Pewter and Lead Free Pewter alloyed with Silver, Indium, and Bismuth, as well as Brittania, and Genuine Pewter

View more

Solders

Featuring: Body solders, Lead-base, Lead-free solders, Low melting solders, Miter-Al-braze (MAB), Tin-Antimony solders, Tin-base, Tin-Cadmium solders, Tin-Lead solders, Tin-Zinc solders

View more

Tin Alloys

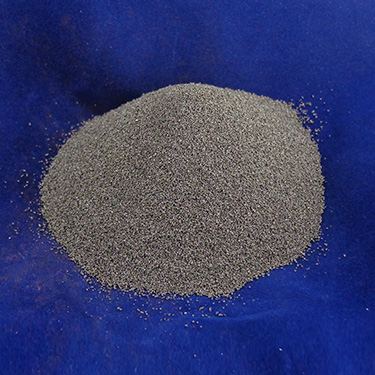

Featuring: jewelry alloys, Sn anodes for plating, Sn shot for gray iron and titanium alloy additions, Grade A and 99.99% Sn, Sn-base babbitts, 5% phosphor Sn, Pewter, Sn-base solders, Sn powder, Sn oxide powder, Sn granular.

View more

White Metals

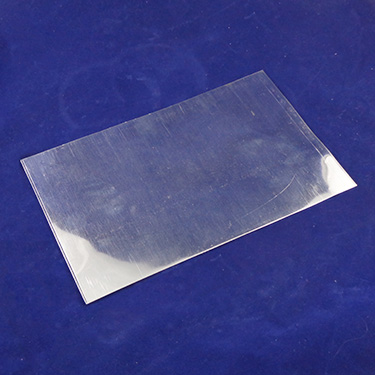

Featuring Aluminum, Lead, Pewter, Solders, Jewelry, Sculpture, Tin, Zinc Alloys in a variety of forms for many applications

View more

Zinc Alloys

Featuring pure Zn shot for precious metal alloying and other uses; Zn plating anodes; Superdie and other Zn alloys for rubber-mold and permanent mold casting, ultrasonic solders.

View more

Lead Alloys

Featuring: 99.99% Lead in a variety of forms, Pb-Base Babbitt and casting alloys for jewelry and ornamental products, 6% Antimonial Lead, Linotype Alloys, and Pb-Base Solders

View more

Bismuth Alloys

Featuring 99.9% Bismuth and Low Melt Eutectic and Non-Eutectic Alloys offering custom compositions and forms

View moreFeatured Products

-

Can be used for various soldering methods including Wave, Selective, and Hand. Known for best in class yields, this material outperforms all Sn/Cu based materials and delivers excellent performance across a wide range of Flux Technologies. SAC305 is used to stabilize the copper content in the wave solder bath depending on process conditions. Forms: - Regular Bar

- Shot

- Ingot

Belmont Product Code 7972 Nominal Composition: - Sn: 96.5%

- Ag: 3%

- Cu: 0.5%

Technical Info: - Solidus: 217 C (423 F)

- Liquidus: 220 C (428 F)

-

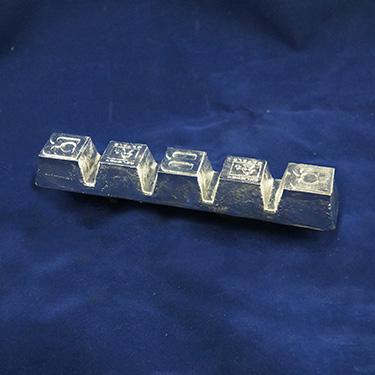

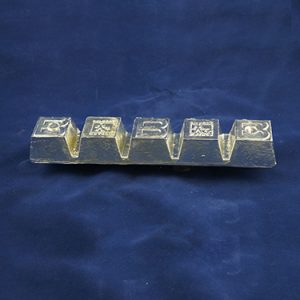

This is our Original, Lead Free, Zinc Based Alloy that works well in Spin Cast Vulcanized Silicone Molds for designs with thick cross sections or minimal detail. Contains Proprietary Grain Refiners for improved casting properties. Forms: - 4-20 lb. KZ Ingot

Belmont Product Code 892NS1 Nominal Composition: - 90-94% Zinc in a Proprietary Formula

Technical Info: - Elongation : 8%

- Liquidus Temperature: 734F

- Pouring Temperatire: 800 F - 875 F

- Density: .244 lbs / Cu. In.

- Tensile Strength: 54,000

- Compression Strength: 68,800 psi

- Brinell Hardness: 146

- Finishes: Mechanical, chemical, organic, and electro-deposited, plastic

-

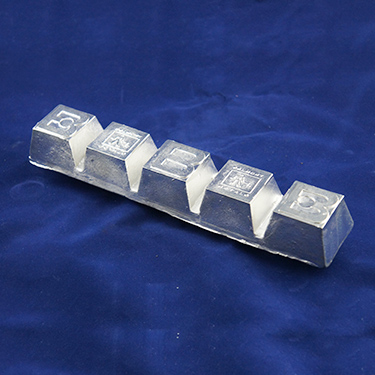

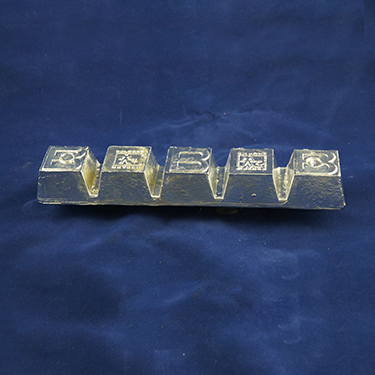

Commercial Zinc base alloy, it contains approximately 15% Aluminum and 85% Zinc. Specially formulated and metallurgically designed to provide superior casting results in Spin-Casting applications. Forms: - 4-16 Ingot

Belmont Product Code 8853 Nominal Composition: - 85% Zn

- 15% Al

-

Slush Cast alloy is a high purpose-engineered product. This alloy was developed to provide a high fluidity casting material capable of producing a good surface definition when cast in metal permanent molds or rubber molds. It contains approximately 5% Aluminum and 95% Zinc. It is used primarily for the use of hollow castings. Forms: - 4-20 Ingot

Belmont Product Code 8952 Nominal Composition: - 95% Zn

- 5% Al

-

Zinc/Aluminum solder 99% Zinc and 1% Aluminum. Used by the Romans and is commonly used today, particularly in musical instruments and many hardware applications that must resist corrosion. Zinc is an alloy with Lead and Tin to make solder, a metal with a relatively low melting point used to join electrical components, pipes and other applications. Forms: - 4-20 Ingot

Belmont Product Code 8995 Nominal Composition: - 99% Zn

- 1% Al

-

Zamak 12 offers high hardness and high tensille strenght. This is the preferred alloy for permanent mold applications although it can also be cold-chamber die-cast with excellent results. It combines low temperature melting efficiency and thin wall capabilities with premium mechanical properties. ZA-12 can usually be poured directly into molds designed for aluminum and brass. Forms: - 4-20 Ingot

Belmont Product Code 8871 Nominal Composition: - 88% Zn

- 11% Al

- 1% Cu

-

Zamak 7 is a modification of Zamak 3. However, Zamak 7 has higher ductility (for Forming and bending operations) and the highest casting fluidity of the Zamak family. Excibits excellent damping capacity and vibration attenuation in comparison with aluminum die casting alloys. Forms: - 4-20 Ingot

Belmont Product Code 8962 Nominal Composition: - 95.87% Zn

- 4.1% Al

- 0.015% Mg

- 0.015% Ni

-

Zamak 3 is a family of alloys with a base metal of zinc and alloying elements of aluminum, magnesium and copper. It is the most commonly used in Zinc die casting, providing an excellent combination of strenght, ductility. It also provides excellent plating and finishing characteristics. This alloy is the designers first choice for die casting applications and the most widely used in North America. Forms: - 4-20 Lb. Ingot

Belmont Product Code 8961 Nominal Composition: - 96% Zn

- 4% Al

-

This Solder has good corrosion resistance and tensile strength. With a melting range beginning at 390 Deg. F. it avoids causing damage to critical electronics as well preventing substrate deformation and segregation. It is used very often in spray wire form for capacitors and other electronic parts. Forms: - 1/16" Dia. Plus .000" Minus .004" on 5 Lb. Spools

- 2-5 Ingot

- Cast Flat Anodes

Belmont Product Code 7601DS1C Nominal Composition: - 60.5% Sn

- 39.5% Zn

-

This is a Bismuth based non-eutectic alloy commonly used as a low-melting solder and also to make custom shaped blocks. It is also used to make metal inlays in wood and also useful for repairing antiques as the low melting temperature of Wood's metal makes it unlikely this will harm the original piece. Forms: - 1/4" Dia. Solid Wire

- 1/8" Dia Solid Wire

Belmont Product Code 2502DS1C Nominal Composition: - 12.5% Sn

- 25% Pb

- 50% Bi

- 12.5% Cd

-

Lead Silver solders such as this have physical properties - tensile, creep, and shear strength - which are good to 350 Deg. F. Fatigue properties are also better than the non silver solder alloys. Forms: - .063 Dia. Solid Wire

- 5Lb. Spools

- Capping Bars

Belmont Product Code 5951DS1C Nominal Composition: - 60% Sn

- 40% Pb

- 5.5% Ag

-

Tin-Lead solders is the largest single group and the most widely used of the soldering alloys . Tin-Lead solders are compatible for use with all types of base metal cleaners, fluxes, and heating methods. 60/40 Tin Lead solder, almost the eutectic is particularly adaptable to delicate work or when soldering temperature may be critical. This particular item comes in 1/16" Diameter and can also be offered in other sizes as well. This is also a quick setting solder for fine electrical and tinsmith work. Forms: - 1/16" Dia. Solid Wire

Belmont Product Code 76001DSC Nominal Composition: - 60% Sn

- 40% Pb

-

-

Belmont Special 92% Tin Pewter alloy is an excellent casting alloy with approximately 92% Tin (Tin base alloy). Special Pewter for figurines, models, etc. with heavy sections - better casting characteristics than lead free Britannia. Forms: - 5-6 Ingot

Belmont Product Code 7924 Nominal Composition: - 92% Sn

- 4% Pb

- 4% Sb

-

Forms: - 5-6 Ingot

- 1/4" and Down Unpolished Irregular Shot

- .05" Dia. Solid Wire 1 Lb. Spools

Belmont Product Code 7921 Nominal Composition: - 91.75% Sn

- 8% Sb

- 0.25% Cu

Technical Info: - Elongation (2" Section) : 20% - 40%

- Liquidus Temperature: 465F - 485F

- Solidus Temperature: 515F - 635F

- Density: .23 - .275 lb. / Cu. In. @ 68F

- Brinell: 18 - 25

- Tensile Strength: 5,000 psi - 8700 psi

- Solderability: Can be soldered Easily with soft solder and flux

- Finishes: Mechanical, chemical, organic, and electroplated

-

-

-

Lead,Tin, Antimony Alloy. Low Melting fusible alloy. Excellent low-cost alloy. High-antimony lead alloy specially treated to increase ductility and fluidity. Useful where casting may be subject to bending. Forms: - 2-8 Ingot

Belmont Product Code 5877 Nominal Composition: - 86.925% Pb

- 10% Sb

- 3% Sn

- 0.0725% Te

-

Lead base alloy for casting bullets and fishing jigs. Linotype will have a brinell hardness and good strength. Used to be used a lot in the printing industry. Forms: - 10-20 Mesh 0.078" x 0.033

- 12-30 Mesh .0661 in. - .032"

- 20-25 Lb. Pig

- 40 Lb. Pigs

- Approx. 40 Lb. Pigs

Belmont Product Code 5841 Nominal Composition: - 84% Pb

- 12% Sb

- 4% Sn

-

Lead shot is available for different applications. Type BB Lead shot prepare for ammunition measure 0.18 inches in diameter. Lead is the most common material for shotgun. Forms: - 0.18" Dia

Belmont Product Code 5010 Nominal Composition: - 99.90% Pb

-

Linotype shot for hydrometals and bullet casting. It is good for varmit cast bullets. Linotype does not have a larger % of tin in it but it really has a larger percentage of antimony that makes for hard and brittle bullets. Forms: - 10-20 Mesh .078" x .033"

Belmont Product Code 58410 Nominal Composition: - 84.25% Pb

- 11.5% Sb

- 4.25% Sn

-

35% Tin Pewter, Lead, Tin Alloy easy meltable with relatively low melting temperature. Offers opportunity for cost savings where its relatively high weight is not a problem . Offers opportunity for cost savings where its relatively high weight is not a problem. Forms: - 5-8 Ingot

Belmont Product Code 5632 Nominal Composition: - 62% Pb

- 3% Sb

- 35% Sn

-

R-8-18 size 0.18" Diameter, but tend to vary in size. It is used for a variety of other purposes with dense material for weight/balance. Due to lead's high desity, it is used to attenuate radiation, especially X-rays. Lead shot may be enclosed in a bag and then placed around a point source for radiation protection or for radiation shielding. Forms: - 8-16 Mesh Shot

Belmont Product Code 5011 Nominal Composition: - 99.90 Pb

-

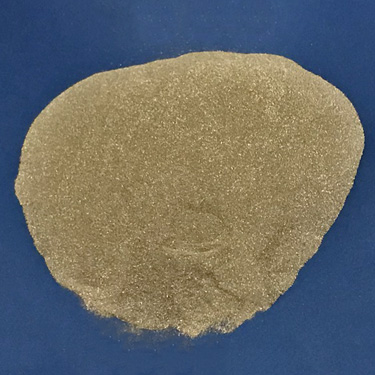

Phosphorus is used in tin as in tin solders to suppress dross formation keeping the metal bath cleaner. Forms: - Waffle

Belmont Product Code 7955 Nominal Composition: - 95% Sn

- 5% P