Master Alloys

Aluminum Master Alloys

with Beryllium, Boron, Boron-Titanium, Chromium, Copper, Iron, Lithium , Magnesium, Manganese, Nickel, Silicon, Titanium, Zinc

View more

Beryllium Copper

Featuring Beryllium Copper Alloys in a Variety of forms; 4% Beryllium Copper, Beryllium Copper Alloys: 20C, 10C, 70C, 165C, 275C and more

View more

Boron Copper

Featuring 2% Boron Copper for use as a deoxidizer and degasifier for copper and nickel-base alloys in a variety of forms

View more

Copper Master Alloys

with: Beryllium, Boron, Cadmium, Chromium, Iron, Lithium, Magnesium, Manganese, Nickel, Phosphorous, Silicon, Tellurium, Titanium, Zinc, Zirconium

View more

Deoxidizers and Degasifiers

Featuring 2% boron-copper and 2% lithium-copper hardeners, master alloys, deoxidizers, and degasifiers.

View more

Lithium Copper

Featuring 2% Lithium Copper for use as a deoxidizer and degasifier for copper and nickel-base alloys in a variety of forms

View more

Zirconium Copper

Zirconium, given its high melting point, is a perfect candidate to be alloyed utilizing a much more workable Copper Zirconium Master Alloy.

View moreFeatured Products

-

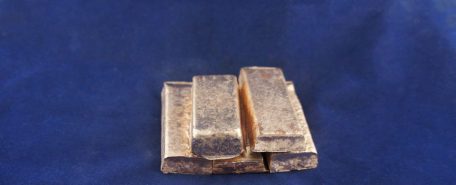

This alloy is used to introduce Titanium into Copper alloys which improves strength. Forms: - 1" x 6" x 12" Slabs

Belmont Product Code 47024 Nominal Composition: - 70% Cu

- 30% Ti

-

-

-

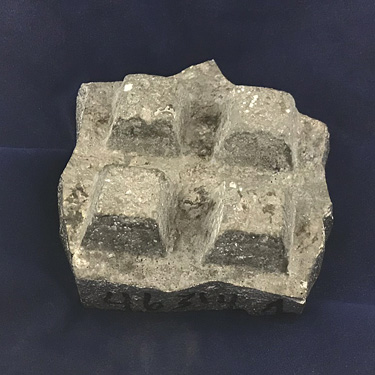

Zirconium acts as a grain refiner in Copper Alloys and can improve mechanical properties. Forms: - 1" x 6" x 12" Broken Slabs

Belmont Product Code 45046 Nominal Composition: - 50% Cu

- 50% Zr

-

Zirconium acts as a grain refiner in Copper Alloys and can improve mechanical properties. Forms: - Broken Slabs

Belmont Product Code 47012 Nominal Composition: - 70% Cu

- 30% Zr

-

-

Zirconium acts as a grain refiner in Copper Alloys and can improve mechanical properties. Forms: - Broken Slabs

Belmont Product Code 49011 Nominal Composition: - 90% Cu

- 10% Zr

-

Compound Degasifier engineered to be effective at removing unwanted gases when used with Nickel Alloys. Forms: - 2" and Down

Belmont Product Code 48515 Nominal Composition: - Proprietary

-

-

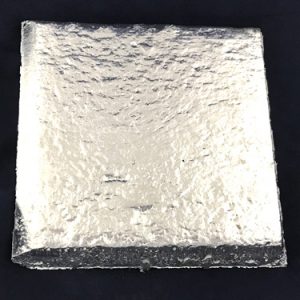

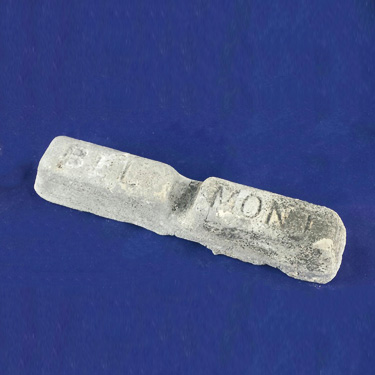

Phosphorus is used in tin as in tin solders to suppress dross formation keeping the metal bath cleaner. Forms: - Waffle

Belmont Product Code 7955 Nominal Composition: - 95% Sn

- 5% P

-

-

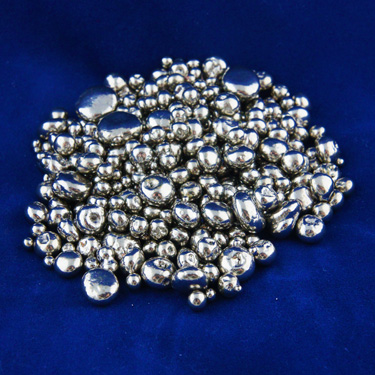

Phos Copper is the most commonly used deoxidizer. Effectively removes oxygen from molten metal with little or no reaction or dross formation. Forms: - 3 Mesh Shot

- Approx. 15 Lb. Waffle Ingots

Belmont Product Code 48514 Nominal Composition: - 85% Cu

- 15% P

-

Lithium has the advantage of being able to combine with both oxygen and hydrogen. Used on its own, Lithium will be more of a deoxidizer. Used in a “duplex treatment”, deoxidizing first, then Lithium can be considered a degasifier now available to be a scavenger for hydrogen and other unwanted gasses. Forms: - 1 Lb. Pcs. 1" X 1" x 4"

- 3-4 Oz. Polished Pieces

- 1" x 6" x 12" Slabs

Belmont Product Code 4981 Nominal Composition: - 98% Cu

- 2% Li

-

-

-

-

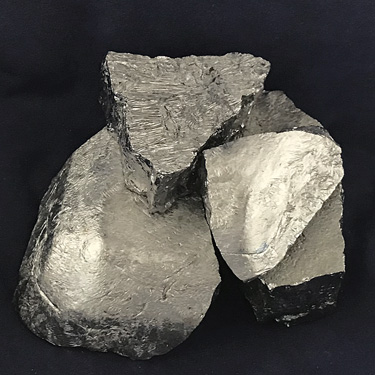

Silicon increases fluidity in brasses and copper nickel alloys. Silicon copper can become a deoxidizer if phosphorous cannot be used. Forms: - 1/2" x 14" Mesh Broken Pieces

- Broken Slabs

Belmont Product Code 4710 Nominal Composition: - 70% Cu

- 30% Si

-

Magnesium is a strong deoxidizer particularly for nickel alloys. As a Copper master alloy it is effective and less reactive. If alloyed, in can improve mechanical properties. Forms: - Broken Slabs

Belmont Product Code 4800 Nominal Composition: - 80% Cu

- 20% Mg

-

-

Chrome is an addition generally made in Copper Alloys for corrosion resistance and electrical conductivity. Forms: - 2-10 Ingot

Belmont Product Code 4906 Nominal Composition: - 90% Cu

- 10% Cr

-

Nickel is known to improve corrosion resistance particularly in sea water. This makes it a good choice to improve the properties of marine alloys. Forms: - 2-14 Mesh Polished Shot

Belmont Product Code 45027 Nominal Composition: - 50% Cu

- 50% Ni

-

A Copper (Cu) Alloy containing Chromium (Cr) used for their high strength and corrosion resistance. It offers high conductivity, good ductivity and strength. Serves as a master alloy to add chrome to various copper alloys. Forms: - 2-20 Ingot

Belmont Product Code 4989 Nominal Composition: - 98.7% Cu

- 1.3% Cr

Technical Info: - CDA #: 81500

- Melting Point (Liquidus): 1985 F, 1085 C

- Melting Point (Solidus): 1967 F, 1075 C

- Density: .319 lb./cu. in. @ 68 F

- Specific Gravity: 8.82

- Thermal Conductivity: 182 Btu./sq. ft./ft./hr/F @ 68 F

- Tensile Strength-ksi: 51

-

Can be considered either a deoxidizer or grain refiner. Generally, for pure copper its role would be deoxidizing but in brasses it’s more of a grain refiner. Forms: - 3/4" & Down Polished Shot

- 3/4" & Down Unpolished Shot

- 40-15 Waffle

- 4-5 Oz Pcs.

Belmont Product Code 4987 Nominal Composition: - 98% Cu

- 2% B

-

Master Alloy used in the production of Copper Alloys for a wide variety of industries. The introduction of Boron to Copper Alloys helps eliminate gas and porosity without the loss of conductivity. Forms: - 1/2" and Down Polished Shot

Belmont Product Code 49817 Nominal Composition: - 98% Cu

- 2% B

-

This material offers the highest strength and hardness of all the BeCu alloys with excellent wear resistance and fluidity. Also offers extremely fine detail pick-up in ceramic or pressure cast processes. This also has the lowest pouring temperature of the BeCu alloys allowing almost any type of molding process to be used. Forms: - 1/2" and Down Polished Shot

- 1/2" X 14 Mesh Unpolished Shot

- 2-5 Ingot

Belmont Product Code 4971 Nominal Composition: - 96.43% Cu

- 2.7% Be

- 0.5% Co

- 0.3% Si

- 0.07% Ti

-

This alloy offers high strength, hardness, wear resistance with excellent fluidity. This alloy is ideal for investment, sand or ceramic casting and provides excellent replication of intricate detail. Forms: - 2-5 Ingot

- 2" Cut Bars

- 1" Cut Bar

- 1/2" Polished Cubes

- 1/2" x 14 Mesh Shot

Belmont Product Code 4977 Nominal Composition: - 97.2% Cu, 2.05% Be, 0.5% Co, 0.25% Si

-

This alloy exhibits good strength, coupled with excellent corrosion resistance and material toughness properties. This comparatively lower percentage Beryllium alloy provides thermal conductivity properties that are far superior to most Aluminum, Magnesium & Steel alloys. Forms: - 2" Cut Bars

- 2-20 Ingot

- 2-5 Ingot

Belmont Product Code 4972 Nominal Composition: - 96.8% Cu

- 0.65% Be

- 2.55% Co

-

With the highest Copper content of all BeCu alloys this alloy offers superior strength and hardness along with superior thermal conductivity. It is recommended for Investment, continuous and centrifugal casting methods. Forms: - 2-5 Ingot

Belmont Product Code 4992 Nominal Composition: - 99.12% Cu

- 0.08% Be

- 0.8% Cr

-

This Beryllium Copper alloy provides good resistance to corrosion along with high strength and hardness. It is very suitable for salt water immersion applications and also offer excellent replication of intricate detail. Forms: - 2" Cut Bars

- 2-5 Ingot

Belmont Product Code 4986 Nominal Composition: - 98% Cu

- 1.7% Be

- 0.3% Co

-

A Beryllium containing copper base master alloy which is used to introduce Beryllium into new melts or to replace Beryllium lost through oxidation in remelts. Forms: - Approx. 1" Pcs.

- 1/2" and Down Shot

- Slabs

Belmont Product Code 4962 Nominal Composition: - 96% Cu

- 4% Be

-

Titanium is a grain refiner for Aluminum and improves mechanical properties. Forms: - 1" x 1" x 3" Sheared Pieces

Belmont Product Code 19512 Nominal Composition: - 94% Al

- 6% Ti

-

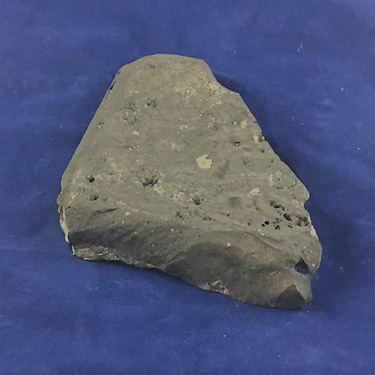

Manganese added to Aluminum increases strength and hardness. It's beneficial in regards to corrosion resistance. Manganese is a grain refiner foir Aluminum. When Manganese is balanced with Iron it can change Iron rich needles to plates increasing ductility. Forms: - 5" x 1/2" Broken Slab

Belmont Product Code 1402 Nominal Composition: - 40% Al

- 60% Mn

-

Lithium added to Alloys containing Magnesium help prevent dross formation. Forms: - 1" x 6" X 12" Slabs

- 2-2 Ingot

Belmont Product Code 19515 Nominal Composition: - 95% Al

- 5% Li

-

-

-

Chromium will improve strength without adversely affecting ductility. Forms: - 1" x 6" x 12" Slabs

Belmont Product Code 18012 Nominal Composition: - 80% Al

- 20% Cr

-

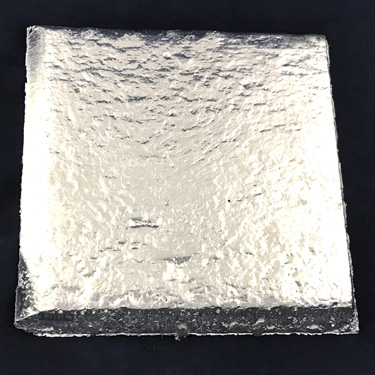

The presence of Iron in Aluminum aides in the decrease of hot tears, improves tensile, yield, and hardness and preserves strength at elevated temperature. Forms: - 16-20 Waffle

Belmont Product Code 19013 Nominal Composition: - 90% Al

- 10% Fe

-

-

Silicon ranks second to Copper in the importance in Aluminum Casting Alloys. Silicon reduces the melting temperature without causing brittleness, increases fluidity, and reduces hot tearing. This improves overall casting characteristics allowing for thinner and more intricate castings to be made. Silicon additions can reduce the amount casting shrinkage and in general Aluminum-Silicon Alloys have been resistance to corrosion. Forms: - 16-17 Waffle

- 30-60 Mesh Granular

Belmont Product Code 1503 Nominal Composition: - 50% Al

- 50% Si