Aluminum-Based Alloys

Aluminum Alloys

Featuring: all standard and special Al alloys—obsolete, prototype, custom customer specification, AA Specifications, small or large lots, Al-base master alloys.

View more

Aluminum Master Alloys

with Beryllium, Boron, Boron-Titanium, Chromium, Copper, Iron, Lithium , Magnesium, Manganese, Nickel, Silicon, Titanium, Zinc

View more

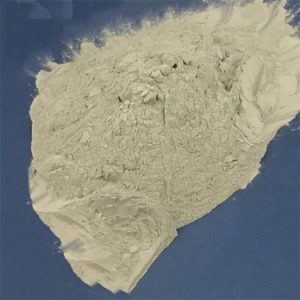

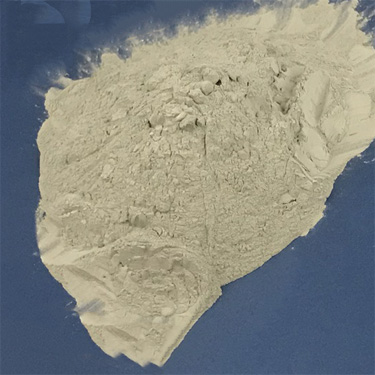

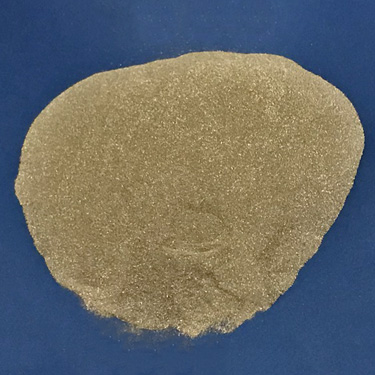

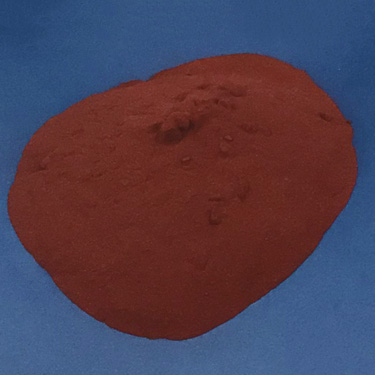

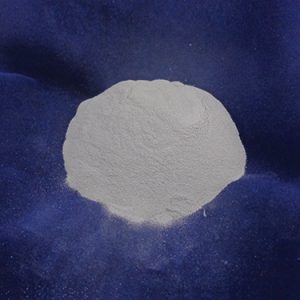

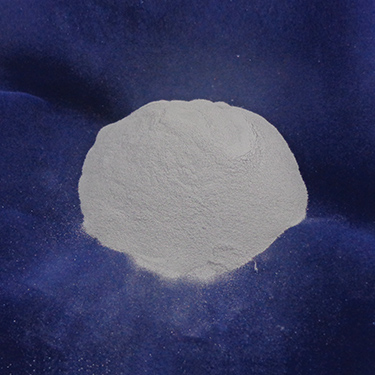

Powdered Metals

Featuring: Holtite Alsil Grit, Iron Powder, High Grade Zinc, Tin, and Copper-Aluminum Applications

View moreFeatured Products

-

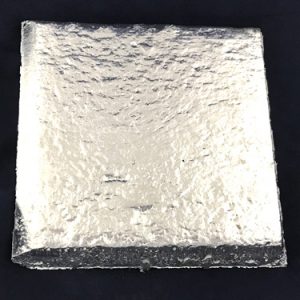

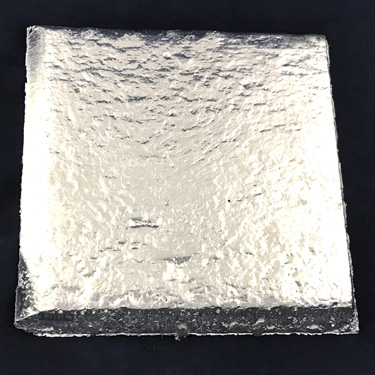

Scalmalloy is a high-performance aluminum alloy designed specifically for additive manufacturing, boasting an outstanding strength-to-weight ratio that’s perfect for aerospace and automotive industries. Its unique blend of superior strength, ductility, and corrosion resistance outperforms traditional aluminum alloys, enabling the production of lightweight, durable components. Ideal for crafting complex geometries, Scalmalloy enhances design flexibility and slashes... Forms: - Ingot

- Waffle

Belmont Product Code Nominal Composition: - Al Bal

- Mg 4%

- Sc 0.7%

- Mn 0.5%

Technical Info: - Good weldability

- High Strength

- Low Density

-

-

-

Titanium is a grain refiner for Aluminum and improves mechanical properties. Forms: - 1" x 1" x 3" Sheared Pieces

Belmont Product Code 19512 Nominal Composition: - 94% Al

- 6% Ti

-

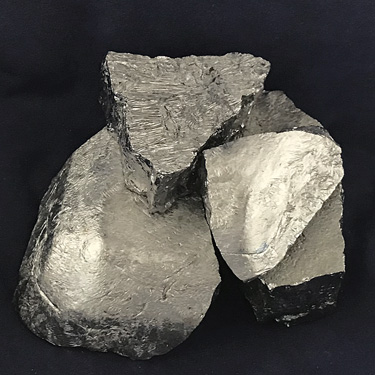

Manganese added to Aluminum increases strength and hardness. It's beneficial in regards to corrosion resistance. Manganese is a grain refiner foir Aluminum. When Manganese is balanced with Iron it can change Iron rich needles to plates increasing ductility. Forms: - 5" x 1/2" Broken Slab

Belmont Product Code 1402 Nominal Composition: - 40% Al

- 60% Mn

-

Lithium added to Alloys containing Magnesium help prevent dross formation. Forms: - 1" x 6" X 12" Slabs

- 2-2 Ingot

Belmont Product Code 19515 Nominal Composition: - 95% Al

- 5% Li

-

-

-

Chromium will improve strength without adversely affecting ductility. Forms: - 1" x 6" x 12" Slabs

Belmont Product Code 18012 Nominal Composition: - 80% Al

- 20% Cr

-

The presence of Iron in Aluminum aides in the decrease of hot tears, improves tensile, yield, and hardness and preserves strength at elevated temperature. Forms: - 16-20 Waffle

Belmont Product Code 19013 Nominal Composition: - 90% Al

- 10% Fe

-

-

Silicon ranks second to Copper in the importance in Aluminum Casting Alloys. Silicon reduces the melting temperature without causing brittleness, increases fluidity, and reduces hot tearing. This improves overall casting characteristics allowing for thinner and more intricate castings to be made. Silicon additions can reduce the amount casting shrinkage and in general Aluminum-Silicon Alloys have been resistance to corrosion. Forms: - 16-17 Waffle

- 30-60 Mesh Granular

Belmont Product Code 1503 Nominal Composition: - 50% Al

- 50% Si

-

Forms: - 3-16 Ingot

Belmont Product Code 18912 Nominal Composition: - 90% Al

- 2% Cu

- 0.8% Mg

- 1.2% Ni

- 6% Sn

-

-

-

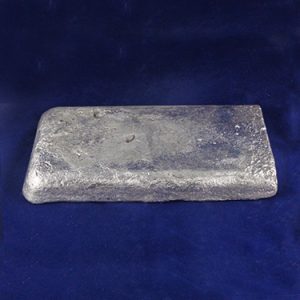

The 200-Series of Aluminum-Copper Alloys are well known for very high strength; nearly double that of the more common 300-Series of Aluminum-Silicon alloys. However, the 200 series can be very difficult to cast. These alloys should be considered where the strength vs. weight ratio is the key consideration such as in the Aerospace and Transportation sector. Forms: - 3-16 Ingot

Belmont Product Code 19215 Nominal Composition: - 92.35% Al

- 5% Cu

- 1.5% Ni

- Bal

-

319 has excellent casting and machining characteristics. Corrosion resistance and weldability are very good and the mechanical properties are good. The anodized color is generally gray with a brown cast depending on the amount and ratio of silicon and copper. Typical applications for sand casting 319.0 are a wide variety of structural castings for engine parts, gas and oil pans, and general commercial applications. Forms: - 22 Lb. Ingot

Belmont Product Code 10319 Nominal Composition: - 90.5% Al

- 3.5% Cu

- 6% Si

-

-

A357 is typically used in situations where high strength combined with high corrosion resistance and/or pressure tightness are required. A357 is commonly used to make parts; including structural, machine, impellers, housings, pump and valve components, tools, frames, and brackets. Forms: - 30 lb Ingot

Belmont Product Code 19320 Nominal Composition: - 92.2%Al

- 7% Si

- 0.6% Mg

- Bal

-

Forms: - Approx. 35 Lb. Ingots

Belmont Product Code 1920 Nominal Composition: - 92.22% Al

- 7% Si

- 0.6% Mg

- Bal

-

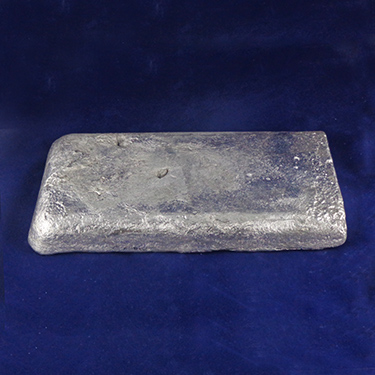

A380 offers the best combination of casting, mechanical, and thermal properties and exhibits excellent fluidity, pressure tightness, and resistance to hot cracking. It is used for a wide variety of products including chassis for electronic equipment, engine brackets, gearbox cases, household furniture, power, and hand tools. Forms: - 3-16 Ingot

Belmont Product Code 18810 Nominal Composition: - 88% Al

- 3.5% Cu

- 8.5% Si

-

-

-

-

The 200-Series of Aluminum-Copper Alloys are well known for very high strength; nearly double that of the more common 300-Series of Aluminum-Silicon alloys. However, the 200 series can be very difficult to cast. These alloys should be considered where the strength vs. weight ratio is the key consideration such as in the Aerospace and Transportation sector. Forms: - Ingot

- Sheared Pieces

- 16-17 Waffle

Belmont Product Code 19413 Nominal Composition: - 94% Al

- 4.5% Cu

- 0.7% Ag

- Bal