Create materials that meet specific needs by adding master alloys to the mix It’s important to choose the right materials for a job. Using inferior or unsuitable materials can make completing a project more difficult or even derail it entirely. In the metals industry, combinations of metals, called alloys, are generated to meet the specific…

|

This alloy offers high strength, hardness, wear resistance with excellent fluidity. This alloy is ideal for investment, sand or ceramic casting and provides excellent replication of intricate detail. |

|

| Forms: |

|

|---|---|

| Belmont Product Code | 4977 |

| Nominal Composition: |

|

|---|

Related products

-

A Beryllium containing copper base master alloy which is used to introduce Beryllium into new melts or to replace Beryllium lost through oxidation in remelts.

Forms: - Approx. 1" Pcs.

- 1/2" and Down Shot

- Slabs

Belmont Product Code 4962 Nominal Composition: - 96% Cu

- 4% Be

-

This alloy exhibits good strength, coupled with excellent corrosion resistance and material toughness properties. This comparatively lower percentage Beryllium alloy provides thermal conductivity properties that are far superior to most Aluminum, Magnesium & Steel alloys.

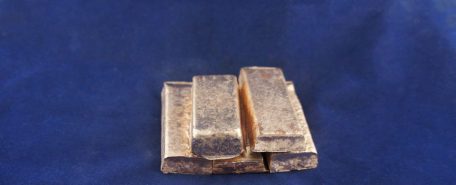

Forms: - 2" Cut Bars

- 2-20 Ingot

- 2-5 Ingot

Belmont Product Code 4972 Nominal Composition: - 96.8% Cu

- 0.65% Be

- 2.55% Co

-

This material offers the highest strength and hardness of all the BeCu alloys with excellent wear resistance and fluidity. Also offers extremely fine detail pick-up in ceramic or pressure cast processes. This also has the lowest pouring temperature of the BeCu alloys allowing almost any type of molding process to be used.

Forms: - 1/2" and Down Polished Shot

- 1/2" X 14 Mesh Unpolished Shot

- 2-5 Ingot

Belmont Product Code 4971 Nominal Composition: - 96.43% Cu

- 2.7% Be

- 0.5% Co

- 0.3% Si

- 0.07% Ti