Babbitt metals are either lead or tin based, and the metal makes excellent bearings that are easy to pour as a DIY project. However, before you pour your bearings, you must select the correct babbitt metal in order to ensure your engine or piece of machinery operates correctly and efficiently. If you know the composition…

Featuring Aluminum, Lead, Pewter, Solders, Jewelry, Sculpture, Tin, Zinc Alloys in a variety of forms for many applications

White metals are any of several light-colored alloys used as a base for plated silverware, ornaments or novelties, as well as any of several lead-based or tin-based alloys used for things like bearings, jewelry, miniature figures, fusible plugs, and many other applications.

White Metal alloys are generally made up of these metals: Antimony, Tin, Cadmium, Bismuth, and Zinc, though which ones being used vary based on the need. As an example, a base metal for jewelry needs to be castable, polishable, have good flow characteristics and have the ability to cast fine detail without an excessive amount of porosity.

Applications: Jewelry Alloys, Pewter, Babbitt Alloys, Fusible Alloys, Tin-Lead Solders, Casting Alloys, Aluminum Joining

Forms: Pig, Ingot, Bar, Cake, Shot, Granular, Mossy

Read More

Showing all 13 results

Featured products

-

Ultra-Pure that exhibit strong inertness and extreme hardness, applied in severe-service conditions requiring excellent strength, high operating temperatures. Typically use for critical applications that requires extreme tight tolerance. Excellent electrical insulators. 99.9% Alumimum is widely used in galvanizing one of the most used methods for protecting metal from corrosion. Forms: - 2-5 Mesh Shot

- 50 Lb. Ingots

Belmont Product Code 1008 Nominal Composition: - 99.9% Al

- Bal

-

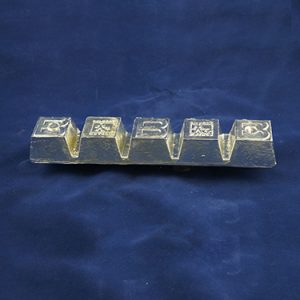

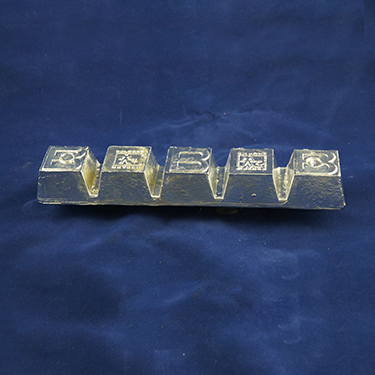

This is a high purity Tin based Lead Free Pewter Alloy, that meets or exceeds most Lead Free requirements. We certify it to be less than 50 ppm Lead Content. It works well in Spin Cast Rubber or Silicone Molds for designs with thick cross sections or a smooth, polished finish and some malleability. Forms: - 4-5 Ingot

Belmont Product Code 798NENTB Nominal Composition: - Sn: 97-99% with Bismuth and Silver in a Proprietary formula

Technical Info: - Elongation (2" Section) : 20% - 40%

- Liquidus Temperature: 465F - 485F

- Solidus Temperature: 515F - 635F

- Density: .23 - .275 lb. / Cu. In. @ 68F

- Brinell: 18 - 25

- Tensile Strength: 5,000 psi - 8700 psi

- Solderability: Can be soldered Easily with soft solder and flux

- Finishes: Mechanical, chemical, organic, and electroplated

-

This is a Lead Free Pewter, also referred to as a Britannia Alloy that works well in Spin Cast Molds for designs, such as Fashion (Costume) Jewelry, with thin cross sections or fine filigree and maximum detail requiring less malleability and more strength. Forms: - 4-5 Ingot

Belmont Product Code 791NR8 Nominal Composition: - Sn: 91-93% with Antimony and Copper in a Proprietary formula enhanced from our standard 7921 Brittania

Technical Info: - Elongation (2" Section) : 30% - 40%

- Liquidus Temperature: 478F - 490F

- Solidus Temperature: 435F - 463F

- Brinell: 21 - 25

- Tensile Strength: 7,000 psi - 9600 psi

- Solderability: Can be soldered Easily with soft solder and flux

- Finishes: Mechanical, chemical, organic, and electroplated

-

For high speed and heavy load applications slightly softer than Grade 1. Forms: - 5-6 Ingot

- 1/8", 1/16", 1/32", 3/16", 5/32" Dia Solid Wire

- Pigs

Belmont Product Code 7881 Nominal Composition: - 89% Sn

- 7.5% Sb

- 3.5% Cu

Technical Info: - ASTM B-23 Grade # : 2

- Melting Point-Solidus : 241 C, 466 F

- Melting Point - Liquidus : 354 C, 669 F

- Pouring Temperature : 425 C, 795 F

-

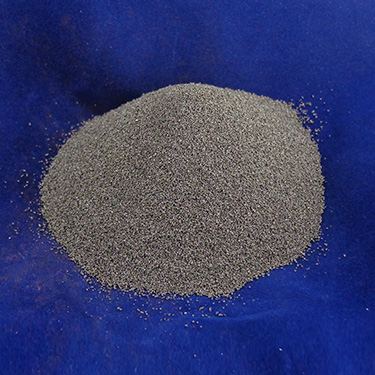

Mainly used in galvanizing steel to prevent rusting, in zinc die casting alloys and in copper based alloys, such as brass. Zinc is also essential to the growth of many kinds of organisms, both plant and animal. Zinc also extends the life of other material such as steel (by hot dipping or electrogalvanizing), rubber and plastics (as an aging inhibitor) and wood (in paints) Forms: - 2-14 Mesh Shot

- 50 lb Slabs

Belmont Product Code 8000 Nominal Composition: - 99.99% Zn

-

This is a Bismuth based Eutectic low melting alloy whose main attribute is the minimal volume change between its liquid and solid state. This is the highest melting point of the bismuth-base alloys commonly used in the industry and provides an easily castable material ready for use soon after it freezes. It is used primarily for holding parts such as jet engine blades for machining and also for foundry patterns and fusible elements in safety devices. Forms: - Cakes

- .063" Dia. Solid Wire on 1 Lb. Spools

- 1/8" x 18" Cast Strips

- 1/8" X Down Shot

- 30 Lb. Pigs

- 5 lb. Ingot

Belmont Product Code 2581 Nominal Composition: - 58% Bi

- 42% Sn

Technical Info: - Melting Point - Solidus 281 F, 138 C

- Melting Point - Liquidus 281 F, 138 C

- Short-Term Tensile Strength lbs/sq.in. 8000

- Yield Temperature 281

- Weight lbs/cu.in 0.315

- Brinnell Hardness No. (500 kg) 22

- Growth/Shrinkage - Time after Casting: after 2 mi.: 0.0007

- after 1 hour: 0.0006

- after 24 hrs: 0.0005

- after 500 hrs: 0.0005

-

A356 has very good casting and machining characteristics. Corrosion resistance is excellent and it has very good weldability characteristics. Mechanical properties are rated excellent. Typically this alloy is used in castings for aircraft parts, pump housings, impellers, high velocity blowers and structural castings where high strength is required. The fact that A356 has good castability makes it a logical choice for intricate and complex castings where lightweight, pressure tightness and excellent mechanical properties are needed. Forms: - Ingot

- Saw Cut Pcs.

Belmont Product Code 10A356P Nominal Composition: - 92.6% Al

- 7% Si

- 0.4% Mg

-

Lead - Antimony alloys have high corrosion resistance in most enviroments. They form a protective, impermeable film even faster than pure lead and in some cases even faster than chemical lead. It is found that except in the presence of florine compunds, 6% antimonial lead is more resistant to corrosion than is soft lead. 6% Antimony, 92% Lead this is by far the most popular with target shooters. Good castability. Somewhat brittle. Moderate cost. Forms: - 2-8 Ingot

- Rods

- Sheet

Belmont Product Code 5933 Nominal Composition: - 93% Pb

- 6% Sb

- 1% Sn

-

-

95/5 Zinc Aluminum M Solder alloy composed of 95% Zinc 5% Aluminum that exhibits remarkable coating corrosion resistance and adhesion. Resistance to corrosion of joints soldered with 95ZN-5AL is superior to that obtainable with other solders; it is comparable to that obtain with pure Zinc. Forms: - 1/4# Capping Bar

- 4-20 Ingot

- Approx. 1 Lb. Regular Bars

Belmont Product Code 8951 Nominal Composition: - 95% Zn

- 5% Al

-

Forms: - 20 Mesh Granular

- 30 Mesh Granular

- 8-20 Mesh Shot

- Mossy

Belmont Product Code 7008 Nominal Composition: - 99.9% Zn

- Bal

Related Products

RELATED POSTS

Antimony: Possessing Durability and Versatility When Alloyed with Other Metals

Semiconductors, machine bearings, and utensils are all made from varying amounts of metal alloys. Yet these items also possess one common factor: antimony. Antimony is a semi-metal element that comes in both a powdered form as well as a hard and brittle metal. Possessing a silvery, blush white appearance, this element is highly desired when…