For jewelry casting, manufacturers have a wide range of base metals and alloys to select from for their pieces. Most common metals that consumers are familiar with are gold, silver, platinum, and sterling silver. Yet there are many other types of alloys that may be used, including tin and zinc. When determining which alloy to…

Featuring: jewelry alloys, Sn anodes for plating, Sn shot for gray iron and titanium alloy additions, Grade A and 99.99% Sn, Sn-base babbitts, 5% phosphor Sn, Pewter, Sn-base solders, Sn powder, Sn oxide powder, Sn granular.

All types of Sn and Sn alloys for additions, alloying, casting chemical, plating, ACS reagent, and soldering uses.

Tin was one of the first metals known to man. Throughout ancient history, various cultures recognized the virtues of tin in coatings, alloys and compounds, and use of the metal increased with advanced technology. Today, Tin is an important metal in industry even though the annual tonnage used is much smaller than those of many other metals. One reason for the small tonnage is that, in most applications, only very small amounts of tin are used at a time.

Solders account for the second largest usage of Tin (after tinplate). Tin is an important constituent in solders because it wets and adheres to many common base metals at temperatures considerably below their melting points. Tin is alloyed with lead to produce solders with melting points lower than those of either tin or lead. Small amounts of various metals, notably antimony and silver, are added to tin-lead solders to increase their strength. These solders can be used for joints subjected to high or even subzero service temperatures.

Applications: Casting, Plating, Solder, Babitt Alloys, Bronze Alloys, ACS Grade for Chemical use Applications, Alloys with Lead, Antimony, Copper, Zinc, Bismuth, Phosphor

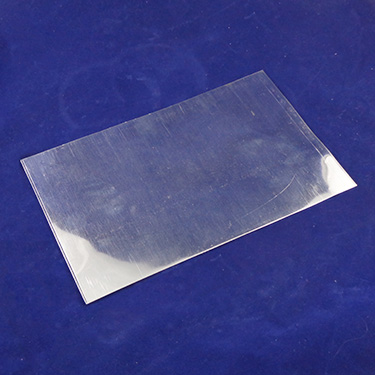

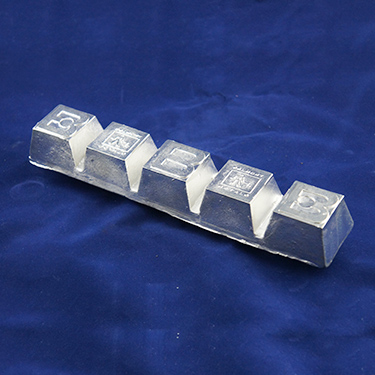

Forms: Pig, Ingot, Bar, Granular, Mossy, Shot, Anodes, Rod, Wire, Powder

Read More

Showing all 18 results

Featured products

-

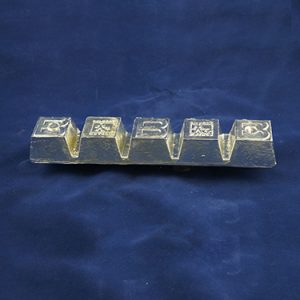

Can be used for various soldering methods including Wave, Selective, and Hand. Known for best in class yields, this material outperforms all Sn/Cu based materials and delivers excellent performance across a wide range of Flux Technologies. SAC305 is used to stabilize the copper content in the wave solder bath depending on process conditions. Forms: - Regular Bar

- Shot

- Ingot

Belmont Product Code 7972 Nominal Composition: - Sn: 96.5%

- Ag: 3%

- Cu: 0.5%

Technical Info: - Solidus: 217 C (423 F)

- Liquidus: 220 C (428 F)

-

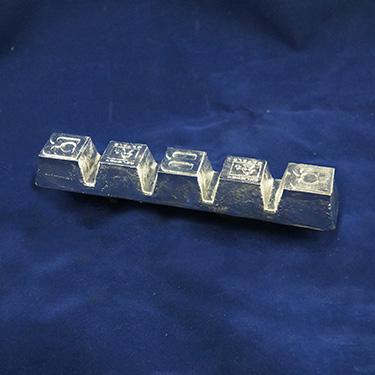

35% Tin Pewter, Lead, Tin Alloy easy meltable with relatively low melting temperature. Offers opportunity for cost savings where its relatively high weight is not a problem . Offers opportunity for cost savings where its relatively high weight is not a problem. Forms: - 5-8 Ingot

Belmont Product Code 5632 Nominal Composition: - 62% Pb

- 3% Sb

- 35% Sn

-

Phosphorus is used in tin as in tin solders to suppress dross formation keeping the metal bath cleaner. Forms: - Waffle

Belmont Product Code 7955 Nominal Composition: - 95% Sn

- 5% P

-

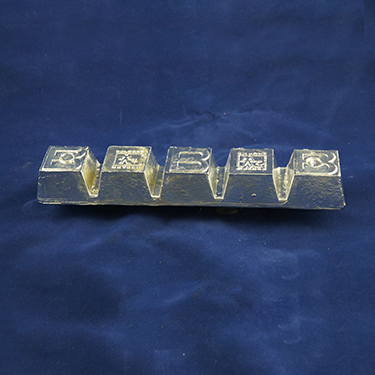

Belmont Special 92% Tin Pewter alloy is an excellent casting alloy with approximately 92% Tin (Tin base alloy). Special Pewter for figurines, models, etc. with heavy sections - better casting characteristics than lead free Britannia. Forms: - 5-6 Ingot

Belmont Product Code 7924 Nominal Composition: - 92% Sn

- 4% Pb

- 4% Sb

-

RELATED POSTS

Manufacturing Benefits of Pure Tin in Shot & Granular Form

When evaluating metals used to strengthen other alloys and to provide unique mechanical and physical properties, tin in higher purities is one metal that manufacturers take a close look at. Tin is an abundant metal as it is used in a number of manufacturing purposes and industries. This metal is often used as an outer…

Benefits of Alloying Ag with Sn Alloys

While tin (Sn) is not mentioned as often as copper, it is another widely used metal for industrial applications. Tin is used most in electroplating, where the metal is used to coat other base metals to provide protection from other factors such as corrosion. Electroplating can also provide a more aesthetically pleasing appearance. The tin…

Shot and Cubed Alloys: Advantages of Using Different Shaped Metals

Due to advanced manufacturing processes, companies today can use a range of base metals and alloys to create the right products and components to their industries. When obtaining the metals that will be used in casting, extruding and forming processes, manufacturers can request the alloys and base metals in various sizes and shapes. Ingots, cubes,…

Selecting the Appropriate Babbitt Alloy

Babbitt metals are either lead or tin based, and the metal makes excellent bearings that are easy to pour as a DIY project. However, before you pour your bearings, you must select the correct babbitt metal in order to ensure your engine or piece of machinery operates correctly and efficiently. If you know the composition…

Antimony: Possessing Durability and Versatility When Alloyed with Other Metals

Semiconductors, machine bearings, and utensils are all made from varying amounts of metal alloys. Yet these items also possess one common factor: antimony. Antimony is a semi-metal element that comes in both a powdered form as well as a hard and brittle metal. Possessing a silvery, blush white appearance, this element is highly desired when…

Keep on rolling

Babbitt metals ensure machinery runs smoothly Bearings play an integral role in machine efficiency by reducing friction between moving parts. The earliest recorded examples of bearing usage date back to the Romans, and in the year 1500, Leonardo da Vinci sketched a design for a helicopter that incorporated ball bearings. Today, common types of bearings…

Safe sparklers

Using lead-free pewter alloys for making jewelry helps alleviate health concerns Adding lead to an alloy can help create characteristics—such as softness and lower melting temperatures—that are useful for many applications. However, lead also is a neurotoxin that is dangerous to animals and humans. Small children are more vulnerable to the effects of lead exposure…