Are you looking for an alternative to lead-based alloys? Many companies are moving away from lead and copper and tin alloys due to the regulations and toxicity associated with the heavy metal, and that often means choosing bismuth. The good news is that bismuth has a relatively low melting point, and it’s durable and malleable…

Featuring Lead Free Pewter and Lead Free Pewter alloyed with Silver, Indium, and Bismuth, as well as Brittania, and Genuine Pewter

Pewter is a malleable metal alloy, traditionally 85 -95% Tin, with the remainder consisting of Copper, Antimony, Bismuth and sometimes, less commonly today, Lead. Silver is also sometimes used. Copper and Antimony act as hardeners while Lead is common in the lower grades of Pewter, which have a bluish tint. It has a melting point, around 338 – 446 F ( 170 – 230 C ), depending on the exact mixture.

Pewter was first used around the beginning of the Bronze Age in the Near East. The earliest piece of Pewter found is from an Egyptian tomb from 1450 BC. Pewters containing Lead are no longer used in items such as cups, plates, or jewelry ) that will come in contact with the human body due to health concerns stemming from the Lead content. Modern Pewters are available that are completely free of Lead, although many Pewters containing Lead are still being produced for other purposes.

Applications:

Pewter is used in decorative objects, mainly collectible statuettes and figurines, game figures, aircraft and other models, (replica ) coins, pendants, and plated jewelry.

Forms:

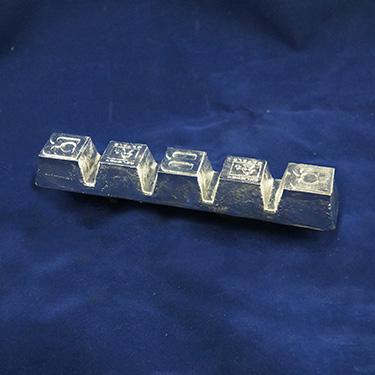

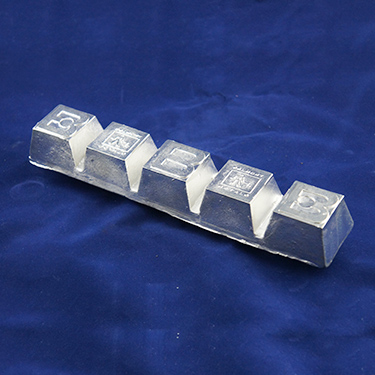

5 Section – 6 Lb. Ingot, 5 Section – 8 Lb. Ingot, Shot

Read More

Showing all 13 results

Featured products

-

Forms: - 5-6 Ingot

- 1/4" and Down Unpolished Irregular Shot

- .05" Dia. Solid Wire 1 Lb. Spools

Belmont Product Code 7921 Nominal Composition: - 91.75% Sn

- 8% Sb

- 0.25% Cu

Technical Info: - Elongation (2" Section) : 20% - 40%

- Liquidus Temperature: 465F - 485F

- Solidus Temperature: 515F - 635F

- Density: .23 - .275 lb. / Cu. In. @ 68F

- Brinell: 18 - 25

- Tensile Strength: 5,000 psi - 8700 psi

- Solderability: Can be soldered Easily with soft solder and flux

- Finishes: Mechanical, chemical, organic, and electroplated

-

-

35% Tin Pewter, Lead, Tin Alloy easy meltable with relatively low melting temperature. Offers opportunity for cost savings where its relatively high weight is not a problem . Offers opportunity for cost savings where its relatively high weight is not a problem. Forms: - 5-8 Ingot

Belmont Product Code 5632 Nominal Composition: - 62% Pb

- 3% Sb

- 35% Sn

-

-

Belmont Special 92% Tin Pewter alloy is an excellent casting alloy with approximately 92% Tin (Tin base alloy). Special Pewter for figurines, models, etc. with heavy sections - better casting characteristics than lead free Britannia. Forms: - 5-6 Ingot

Belmont Product Code 7924 Nominal Composition: - 92% Sn

- 4% Pb

- 4% Sb

-

RELATED POSTS

The Use of White Bronze VS Pewter for Art Casting Applications

When it comes to casting applications, do you know which is better, white bronze or pewter? The most popular choice today and in the past has been pewter, but the use of white bronze has increased in recent years. Here at Belmont Metals, we have both white bronze and pewter that’s perfect for all your…

The Versatility of Pewter: Alloy Types for Decorative Applications

When it comes to decorative alloys, pewter has made a comeback in recent years in the jewelry and crafting industries. This versatile alloy can be found throughout the jewelry world as plated rings, necklaces and bracelets. It is also fashioned into medals, pendants, figurines, statues, and replica coins. Many people may not actually know that…

Safe sparklers

Using lead-free pewter alloys for making jewelry helps alleviate health concerns Adding lead to an alloy can help create characteristics—such as softness and lower melting temperatures—that are useful for many applications. However, lead also is a neurotoxin that is dangerous to animals and humans. Small children are more vulnerable to the effects of lead exposure…