As the holiday season approaches, the sparkle of holiday decorations transforms homes and public spaces into enchanting displays of joy and tradition. At Belmont Metals, we specialize in supplying high-quality non-ferrous metals and alloys that form the backbone of these festive creations. For metal buyers and engineers seeking durable, aesthetically superior materials, our product line…

Featuring: Art Caster’s Brass, Beryllium Copper, Brittania, Electrolytic Copper, Everdur, Jeweler’s Manganese Bronze, Nickel-Silver, Pewters, Superdie Zinc Alloys, and White Bronze

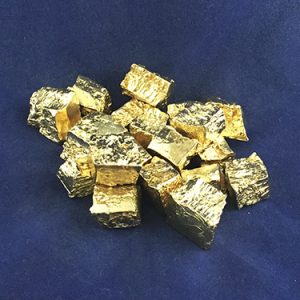

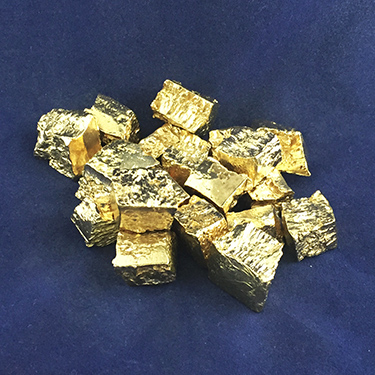

Brass, Bronze, and White Metal alloys have been used in the manufacture of Non Precious Metal fashion jewelry for centuries. Brass & Bronze come in a wide variety of colors including, Dark Red, Yellow, and White. Belmont Special H Silicon Bronze is a Dark Warm Red Color, our Silicon Bronze Everdur is a lighter Red, our Art Casters Brass is Golden Yellow, and Silicon Brass is Yellow in color. Custome formulations can be made in heats as small as 100 lbs for trial purposes. Our White Bronze alloy is similar in color to stainless steel and takes a patina and can be custom colored.

We also have a variety of products manufactured specifically for Karat Gold Alloying. We offer Copper, Tin, Nickel, and Zinc Shot. Belmont offers a line of Virgin Grade Master Alloys including Copper, Nickel, Silicon Copper, Boron Copper, and Cobalt Copper for alloying with Gold for custom colors, specific casting charecteristics to meet most any requirement.

Applications: Non Precious Metal Fashion Jewelry and additions to Gold for Karat Gold alloying

Forms: Ingot, Cut Bar, Cubes, Shot

Read More

Showing all 30 results

Featured products

-

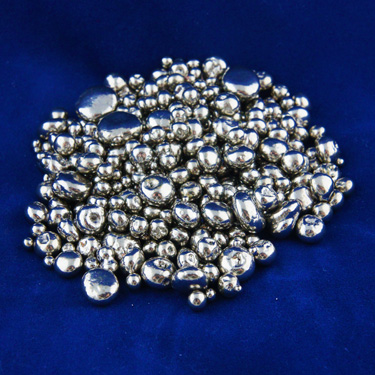

Master Alloy used in the production of Copper Alloys for a wide variety of industries. The introduction of Boron to Copper Alloys helps eliminate gas and porosity without the loss of conductivity. Forms: - 1/2" and Down Polished Shot

Belmont Product Code 49817 Nominal Composition: - 98% Cu

- 2% B

-

-

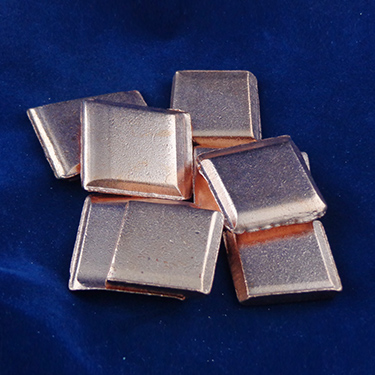

Nickel is known to improve corrosion resistance particularly in sea water. This makes it a good choice to improve the properties of marine alloys. Forms: - 2-14 Mesh Polished Shot

Belmont Product Code 45027 Nominal Composition: - 50% Cu

- 50% Ni

-

-

Easily cast White Brass Alloy with good fluidity and high detail. We offer this material in a variety of forms including Ingot, Cut Bars, Cubes and Shot. Forms: - Ingot

- 2" Cut Bar

- 1/2" Polished Cubes

- Shot

Belmont Product Code 45815 Nominal Composition: - Cu: 58%

- Mn: 20%

- Zn: 20%

- Al: 1%

- Pb: 1%

-

This is our Original, Lead Free, Zinc Based Alloy that works well in Spin Cast Vulcanized Silicone Molds for designs with thick cross sections or minimal detail. Contains Proprietary Grain Refiners for improved casting properties. Forms: - 4-20 lb. KZ Ingot

Belmont Product Code 892NS1 Nominal Composition: - 90-94% Zinc in a Proprietary Formula

Technical Info: - Elongation : 8%

- Liquidus Temperature: 734F

- Pouring Temperatire: 800 F - 875 F

- Density: .244 lbs / Cu. In.

- Tensile Strength: 54,000

- Compression Strength: 68,800 psi

- Brinell Hardness: 146

- Finishes: Mechanical, chemical, organic, and electro-deposited, plastic

RELATED POSTS

Jewelry Casting: Advantages of Tin Alloys vs Zinc Alloys

For jewelry casting, manufacturers have a wide range of base metals and alloys to select from for their pieces. Most common metals that consumers are familiar with are gold, silver, platinum, and sterling silver. Yet there are many other types of alloys that may be used, including tin and zinc. When determining which alloy to…

Can Using Nickel Alloys for Jewelry Cause Problems?

When Baron Cronstedt originally extracted nickel in 1751, he intended to produce copper. That’s why he called this newly discovered metal kupfernickel, a German word that roughly translates in English to “devil’s copper.” Even though nickel’s a very useful and popular metal, the name might almost appear ironic to some people in modern times. Though…

Bell Metals: Properties and Uses in the Musical Industry

When out for a walk by a church or watching a marching band in a parade, you may have listened to the deep ringing tones of a bell or strikes against a cymbal. Such melodious vibrating sounds are created due to the specific type of metal that is used. Bell metals have been around for…

Shot and Cubed Alloys: Advantages of Using Different Shaped Metals

Due to advanced manufacturing processes, companies today can use a range of base metals and alloys to create the right products and components to their industries. When obtaining the metals that will be used in casting, extruding and forming processes, manufacturers can request the alloys and base metals in various sizes and shapes. Ingots, cubes,…

The Use of White Bronze VS Pewter for Art Casting Applications

When it comes to casting applications, do you know which is better, white bronze or pewter? The most popular choice today and in the past has been pewter, but the use of white bronze has increased in recent years. Here at Belmont Metals, we have both white bronze and pewter that’s perfect for all your…

The Difference Silicon Bronze and Silicon Brass for Art Casting Applications

Craftspeople have been casting with bronze for so long that the BBC called it the “first alloy.” Introduced around 3,500 BC and typically made with mostly copper and tin, items made with bronze offered a more durable alternative to coper alone. Artifacts from brass have been dated to 500 BC. Brass may have been favored…

Gold Karat Alloying: Adding Master Alloys and Virgin Additives to Enhance Characteristics

The beauty and rarity of gold is well-known. It’s treasured by jewelers due to its brilliant color and historians who are in search of antique coins. For everyday applications, gold is found throughout our lives in smart phones, laptops and other electronics as this metal is crafted into gold-plated circuit boards. Applications will use gold…

The Versatility of Pewter: Alloy Types for Decorative Applications

When it comes to decorative alloys, pewter has made a comeback in recent years in the jewelry and crafting industries. This versatile alloy can be found throughout the jewelry world as plated rings, necklaces and bracelets. It is also fashioned into medals, pendants, figurines, statues, and replica coins. Many people may not actually know that…

Art Casting with Bronze and Brass

Creating art using the casting process dates back thousands of years as the oldest surviving piece of cast art dates back to 3200 BC. Yet artists today still enjoy creating a range of decorations, statues, figurines, jewelry and other artistic pieces using this process. The procedure involves using molten metals that are poured into a…

Brass and Bronze for Casting Alloys in Decorative Applications

When talking about brass and bronze, we most often think about these alloys in industrial settings, such as bronze industrial bushings and bearings, or brass valves and plumbing fixtures. Yet walk into a museum and will be surrounded by sculptures made out of bronze, or attend a classical opera and you will see brass instruments….

Nickel in Alloys For Jewelry Makers: Looking for Safer Alternatives

No matter the latest fashion trends hitting the New York and Paris runways, every model will have one thing in common: the jewelry they wear. Jewelry manufacturing is a booming business as adults and children of all ages are looking for the right jewelry to wear for everyday activities, special occasions and to have as…

Safe sparklers

Using lead-free pewter alloys for making jewelry helps alleviate health concerns Adding lead to an alloy can help create characteristics—such as softness and lower melting temperatures—that are useful for many applications. However, lead also is a neurotoxin that is dangerous to animals and humans. Small children are more vulnerable to the effects of lead exposure…