Copper’s immense popularity in products made around the world requires manufacturers to develop this alloy in high quantities to meet rising demand. However, copper by itself is often not suitable for products when it is melted and cast into shape. Its soft properties require strengthening yet also elasticity so it does not become brittle. In…

Featuring 2% boron-copper and 2% lithium-copper hardeners, master alloys, deoxidizers, and degasifiers.

A deoxidizer is a compound used in a reaction to remove oxygen. These products contain one or more elements that are scavengers for oxygen decreasing the presence of dissolved oxygen in molten metal. Degasifiers can remove oxygen and other unwanted gases such as hydrogen as well.

Binary Master Alloys as Deoxidizer – Common foundry deoxidizers are Phosphorous copper, Silicon coopers, and Boron copper.

Binary Master Alloys as Degasifier – Li Copper is an excellent deoxidizer but has the added advantage to become a scavenger for other unwanted gases as well. Lithium pre-alloyed with copper is effective as a degasifier with low reactivity.

Special Belmont Degasifiers – Compound degasifiers engineered to be effective at removing unwanted gases when used in the family of alloys they name.

Applications:

Deoxidizers and Degasifiers are used to eliminate gas holes, porosity and metal oxides, while providing the benefit of increased fluidity.

Forms:

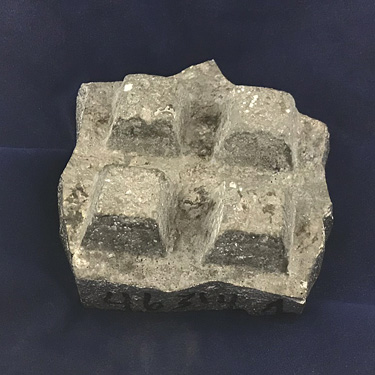

Shot, Waffle, Lumps

Read More

Showing all 23 results

Featured products

-

Lithium has the advantage of being able to combine with both oxygen and hydrogen. Used on its own, Lithium will be more of a deoxidizer. Used in a “duplex treatment”, deoxidizing first, then Lithium can be considered a degasifier now available to be a scavenger for hydrogen and other unwanted gasses. Forms: - 1 Lb. Pcs. 1" X 1" x 4"

- 3-4 Oz. Polished Pieces

- 1" x 6" x 12" Slabs

Belmont Product Code 4981 Nominal Composition: - 98% Cu

- 2% Li

-

Can be considered either a deoxidizer or grain refiner. Generally, for pure copper its role would be deoxidizing but in brasses it’s more of a grain refiner. Forms: - 3/4" & Down Polished Shot

- 3/4" & Down Unpolished Shot

- 40-15 Waffle

- 4-5 Oz Pcs.

Belmont Product Code 4987 Nominal Composition: - 98% Cu

- 2% B

-

Master Alloy used in the production of Copper Alloys for a wide variety of industries. The introduction of Boron to Copper Alloys helps eliminate gas and porosity without the loss of conductivity. Forms: - 1/2" and Down Polished Shot

Belmont Product Code 49817 Nominal Composition: - 98% Cu

- 2% B

-

-

Phos Copper is the most commonly used deoxidizer. Effectively removes oxygen from molten metal with little or no reaction or dross formation. Forms: - 3 Mesh Shot

- Approx. 15 Lb. Waffle Ingots

Belmont Product Code 48514 Nominal Composition: - 85% Cu

- 15% P

-

-

-

Compound Degasifier engineered to be effective at removing unwanted gases when used with Nickel Alloys. Forms: - 2" and Down

Belmont Product Code 48515 Nominal Composition: - Proprietary

-

Zirconium acts as a grain refiner in Copper Alloys and can improve mechanical properties. Forms: - Broken Slabs

Belmont Product Code 49011 Nominal Composition: - 90% Cu

- 10% Zr

-

-

Zirconium acts as a grain refiner in Copper Alloys and can improve mechanical properties. Forms: - 1" x 6" x 12" Broken Slabs

Belmont Product Code 45046 Nominal Composition: - 50% Cu

- 50% Zr

-

Phosphorus is used in tin as in tin solders to suppress dross formation keeping the metal bath cleaner. Forms: - Waffle

Belmont Product Code 7955 Nominal Composition: - 95% Sn

- 5% P

RELATED POSTS

Zirconium: An Alloying Element with Copper Alloys

Copper alloys are widely used metals for manufacturing purposes around the world. From copper pipes, electrical wires, mechanical components and other applications, manufacturers are creating the products for companies to run their operations and for the public to improve their daily lives. This unique alloy offers excellent thermal and electrical capabilities. Other elements will also…

The Properties of Boron and How Its Used as an Alloying Agent

Are you looking for high-quality copper boron that can be easily mixed with other metals in order to create custom alloys? If you are, we offer 2 percent boron copper, which is a great degassifier, deoxifier and grain refiner. Boron: Uses and Properties Boron is a non-metallic element located in group 13, period 2, block…

Zirconium: Deoxidation and Corrosion Resistance Properties for Copper

Metals such as copper are very popular in a range of industries including manufacturing, plumbing and construction. However, it can be prone to deformations when hot worked or during machining. The deformations can cause the metal to fail to keep its desired shape and impact its structure, especially during pipe bending processes. Adding zirconium can…

Lithium’s Properties and Alloying Capabilities in Manufacturing Processes

When discussing lithium, most people associate this element to the lithium batteries that are found in computing devices such as laptops, smartphones and tablet devices. Yet lithium is a metal that is used throughout a range of commercial, manufacturing and industrial processes including the aviation and aerospace industries. The Properties of Lithium Lithium is considered…

Zirconium adding resistance capabilities to copper for an increase in hardness while handling higher temperatures

Name a metal alloy that has been used for centuries, and many people will think of aluminum, iron or copper. Yet Zirconium should also be added to the list. There are numerous products in our workplaces and our homes that uses this silvery-gray metal, such as lamp filaments, television glass, and even in some deodorants….

Lithium Copper Improving Alloy Quality for Better Product Manufacturing

Working with various copper, pure copper and nickel-based alloys allow for manufacturers to create end products for customers and the necessary components for their operations. However, one issue that companies experience is alloy quality during the melting and casting process. When copper and nickel-based alloys are melted, oxygen becomes introduced into the alloys from the…

Deoxidation of Copper Alloys

The deoxidation of copper alloys involves removing the oxygen using a chemical process, usually other metals. As the oxygen and other gases are removed from the metal, certain properties are either enhanced or decreased. For example, when Phosphor is added to bronze alloys, it reacts by removing the oxygen content from the metal which can…

The right metal for the job

Custom alloys can help streamline production Although custom alloys often are associated with new and advanced applications, they also can solve real-world production problems. For more than a century, Belmont Metals, based in Brooklyn, New York, has been working collaboratively with its customers to create materials that can improve their manufacturing processes. Coming up with…

Bring out the best

Master alloys help copper shine Red metals have played an important role in many cultures, including those of the ancient Egyptians and Romans, who crafted tools, cookware, dishes, mirrors and razors out of copper. Modern uses for copper include electrical, heating/cooling applications, fluid handling and plumbing applications, as well as an increasing demand for the…

Controlling composition using Master Alloys

Create materials that meet specific needs by adding master alloys to the mix It’s important to choose the right materials for a job. Using inferior or unsuitable materials can make completing a project more difficult or even derail it entirely. In the metals industry, combinations of metals, called alloys, are generated to meet the specific…