Are you considering plating metals? The process of metal plating is performed to improve corrosion resistance, add aesthetic appeal, enhance the metal’s hardness, reduce friction in moving pieces, increase or decrease conductivity and to improve solderability. The most common plating metals include brass, bronze, cadmium, nickel and tin, and here at Belmont Metals, we sell…

Featuring 99.95%, 99.2%, and 99% Cadmium in a variety of forms

Cadmium is a silver-gray crystalline solid suitable for use in corrosion protection applications such as steel electroplating or the mechanical plating of fasteners and other parts. A variety of standard and custom Cadmium alloys for plating, vacuum plating, alloying, and additions applications are available. Cadmium Oxide is also available for plating, additions, and chemical uses.

Applications: It can also be used in the production of low-melting alloys, brazing alloys, and bearing alloys, and as an alloying ingredient to Copper to improve hardness.

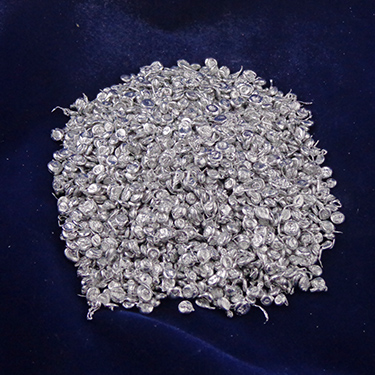

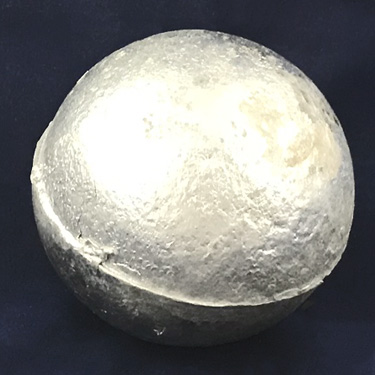

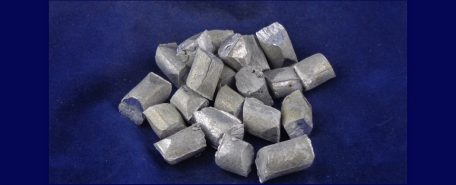

Forms: Cadmium and Cadmium Alloys are offered in various sizes as Anodes (ball, flat, cast rectangular, oval, round, stick) mossy, pellets and sticks for vacuum deposition, powder, slab, shot, and wire. Cadmium Oxide is offered in powder form.

Read More

Showing all 9 results

Featured products

RELATED POSTS

Benefits of Minor Metals for Your Manufacturing Business

Using minor metals from Belmont Metals in Brooklyn, NY can greatly improve your manufacturing process. These metals are often added to master alloys to improve certain desirable properties. For example, electrolytic manganese is often added to steel, aluminum and copper master alloys in order to increase the metal’s ferromagnetic properties. Types of Minor Metals and…