At Belmont Metals, we’re committed to supplying innovative metals and alloys that drive efficiency for metal buyers and engineers in demanding industries. Today, we’re spotlighting low melting alloys, particularly bismuth-based formulations, and their transformative role in oil field completions. As a reliable provider of custom low melting alloys, Belmont Metals helps optimize well integrity and…

Featuring: 99.9% and 99.99% Bismuth in a variety of forms

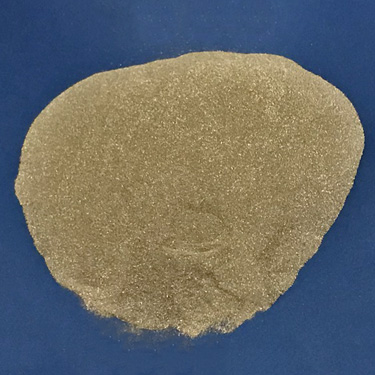

In the Earth’s crust, bismuth is about twice as abundant as gold. In nature, it occurs in its native (free elemental) form, and also as its compounds. It is often associated with the ores of lead, tin, and copper. It’s most important ores are bismuthinite (a sulfide) and bismite (an oxide).

It is usually not economical to mine bismuth as a primary product. Rather, it is most often obtained as a byproduct of the processing of other metal ores, especially lead, or other metal alloys. Like lead (but to a much lesser extent), it is radiogenic, being formed from the natural radioactive decay of uranium and thorium.

Bismuth has several very important uses. Some salts of Bismuth have been found to be beneficial in the treatment of indigestion and other minor ailments of the alimentary canal. Bismuth is also used as an alloy with lead, cadmium and other metals in the manufacture of low melting temperature Fusible alloys, which are heavily used for making parts in the aeronautical industry. Bismuth is added to certain aluminum alloys to improve machinability and also to other metals for specialized uses and Bismuth salts are used in a range of catalysts.

Read More

Showing all 11 results

Featured products

RELATED POSTS

Advantages of Eutectic Alloys vs. Non-Eutectic Alloys to Low Melting Materials

Eutectic alloys and non-eutectic alloys are categories when discussing low melting alloys. Low melting alloys require lower temperature ranges to melt, anywhere from 40 degrees to 300 degrees Fahrenheit. This property allows for the alloys to be melted at lower temperatures without damaging or impacting other nearby materials or surfaces that the low melting alloy…

Why Companies Are Switching from Lead to Bismuth for Copper and Tin Alloys

Are you looking for an alternative to lead-based alloys? Many companies are moving away from lead and copper and tin alloys due to the regulations and toxicity associated with the heavy metal, and that often means choosing bismuth. The good news is that bismuth has a relatively low melting point, and it’s durable and malleable…

Pure Bismuth: Characteristics of This Metal

Bismuth is an element that we often hear about in offhand ways yet don’t know a lot about at first. It is a crystalline element that comes in various colors ranging in white, purple, pink and silver. In its pure form, people will often think it is lead. Bismuth is widely used in the manufacturing…

Different Properties of Low Melting Alloys

Joining metal parts together with solder, easily bending pipes to go around corners and components, and lens blocking systems all rely on the use of low melting alloys. This type of metal allows for products, parts and components to be manufactured and cast at lower temperatures. This feature is ideal when requiring lower temperatures to…

Bismuth-Based Low Melting Alloys Providing Benefits to the Art Casting Industry

Throughout history, art casting has been used to create beautiful works of art, to recreate previous works of art that may have become damaged or deteriorated due to age, or when mass-producing art pieces. The art casting method involves using wood, stone, plaster, or silicon rubber molds and some type of pliable material, such as…

Liquid metal’s low melting point

Fusible alloys’ low melting point makes them useful in a wide variety of applications The melting point of aluminum is 1,220 degrees Fahrenheit. Carbon steel melts somewhere between 2,600 and 2,800 degrees Fahrenheit, and the temperature needs to rise all the way up to 6,150 degrees Fahrenheit to melt tungsten. Specialized furnaces are needed to…

The Basics of Bismuth

This white element is an essential part of many alloys Purple-Silver, crystalline Bismuth has been in use since the early days of alloying, although during those times, it was often mistaken for Lead. It’s the most naturally diamagnetic element, which means it repels both north and south, and it has one of the lowest values…