Are you considering plating metals? The process of metal plating is performed to improve corrosion resistance, add aesthetic appeal, enhance the metal’s hardness, reduce friction in moving pieces, increase or decrease conductivity and to improve solderability. The most common plating metals include brass, bronze, cadmium, nickel and tin, and here at Belmont Metals, we sell…

Featuring a wide variety of alloys and shapes for all electroplating processes including INCO Nickel, High Grade Zinc, CDA 101 Copper.

The electroplating process consists of the immersion of an object to be coated in a bath containing an anode. The object itself functions as the cathode. The bath is usually an aqueous solution of salts of the metal to be deposited. An electrolytic cell is produced when voltage is applied to the anode. The cathode being negative. Metal ions formed in the solution are attracted to the cathode where they gain electrons and deposit out of the solution onto the cathode surface as pure metal. Belmont Metals has been a manufacturer of Electroplating Anodes suitable for a wide variety of end uses for almost 100 years.

Belmont Metals offers various metals & alloys for Electroplating such as Cadmium, Cadmium-Tin, Copper, Phosphorized Copper, Brass & Bronze, Lead, Antimonial Lead, Nickel, Tin , Zinc, and numerous Tin-Lead and Tin-Zinc solders.

Forms Available:

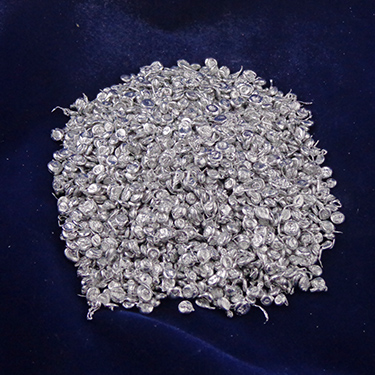

Balls, Cathodes, Pellets, Flat Tops, Nuggets, Rounds, Oval and Flat Anodes, Rod, Bar, and Squares.

All shapes not available in all metals and alloys.

Read More

Showing all 16 results

Featured products

-

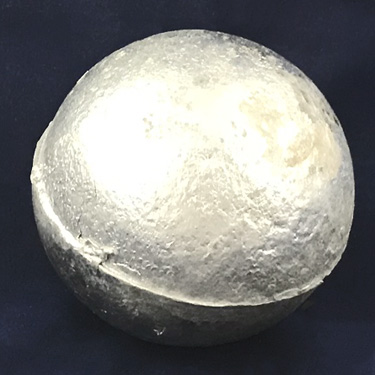

Zinc metal coatings provide better protection on Iron and Steel than any other corrosion resistant coatings. Plated SHG Zinc coatings are pure compared to hot dipped and are also thinner and more ductile, which allows them to be made brighter and more lustrous. We offer this material in 2" diameter balls that are solid and clean and do not have any flash orgates which would cause backet hang ups. Forms: - 2" Diameter Balls

Belmont Product Code 8000AG Nominal Composition: - 99.99% Zn

-

Brass, which is an alloy made of copper and zinc, can be varied to create a wide range of brasses with varying properties, is widely used for decorative applications in antiques and ox finishes. Brass plating is also a great alternation for sealing zinc die-castings for post molding operations. Brass plating provides an excellent diffusion barrier preventing components of the base material from migrating into the subsequent plating layers. Forms: - 1" x 1" x 1" Nuggets

- Cast Flat Top Anode Approx 1-1/4" Each

Belmont Product Code 47018A Nominal Composition: - 30% Zn

- 70% Cu

Technical Info: - CDA #: 96400

-

Brass, which is an alloy made of copper and zinc, can be varied to create a wide range of brasses with varying properties, is widely used for decorative applications in antiques and ox finishes. Brass plating is also a great alternation for sealing zinc die-castings for post molding operations. Brass plating provides an excellent diffusion barrier preventing components of the base material from migrating into the subsequent plating layers. Forms: - Cast Flat Top Anode Approx 1-1/4" Each

- 1" x 1" x 1" Nuggets

Belmont Product Code 48012A Nominal Composition: - 20% Zn

- 80% Cu

Technical Info: - CDA #: 87300

-

Mainly used in galvanizing steel to prevent rusting, in zinc die casting alloys and in copper based alloys, such as brass. Zinc is also essential to the growth of many kinds of organisms, both plant and animal. Zinc also extends the life of other material such as steel (by hot dipping or electrogalvanizing), rubber and plastics (as an aging inhibitor) and wood (in paints). Forms: - Flat Tops

Belmont Product Code 8000AM Nominal Composition: - 99.99% Zn

RELATED POSTS

A Brief Guide to Understanding the Electroplating Process

Electroplating refers to a process used to bind a layer of one metal over the surface of another one. Electroplating changes the properties of an item’s surface, providing protection, improving its appearance, or very often, both. Besides creating a protective coating for a metal item, manufacturers also might use electroplating to increase its thickness or…

Electroplating Advantages: Using Different Coating Products to Provide Enhanced Benefits

You would be surprised just how many items in our lives have electroplating. From your car when driving to work to the jewelry worn on special occasions, commercial manufacturing processes rely on this process to protect metals, as well as plastics, by coating them with an exterior layer of metal. While the most well-known reason…

What is electroplating?

Electroplating refers to a process that adds a surface layer of metal to another type of metal. It’s typically used to prevent corrosion and rust and to extend the useful life of the metal underneath the electroplated metal. Of course, it’s also used to make gold and silver plated jewelry and knickknacks and to give…

Electroplating with Tin Anodes: Uses and Examples

Machinery used in manufacturing applications can consist of a range of metals and alloys that provide strength, electrical and thermal conductivity, durability, workability and other characteristics. However, the metal part itself could be detrimentally impacted by the environment and the working application itself. In other instances, the metal part could create problems if it comes…