As a trusted supplier to the Defense Logistics Agency (DLA), we’re excited to share insights into what it means to hold this prestigious role, especially in delivering top-tier marine anodes for cathodic protection. Our commitment to excellence ensures that your projects—whether in naval, commercial marine, or industrial applications—benefit from reliable, corrosion-resistant solutions. In this newsletter,…

Featuring Mil Spec zinc anodes, MIL-DTL-18001 (Type ZHS, ZHB, ZSS, ZEP, and more) and ultra-pure anodes to ASTM B418 Type II.

Belmont Metals has been a leading manufacturer of Zinc Cathodic Anodes. Cathodic Protection, also referred to as a sacrificial cathode, is a technique used to control the corrosion of a metal surface by making it the cathode of an electrochemical cell. A simple method of protection connects protected metal to a more easily corroded “ sacrificial metal “ to act as the anode. The sacrificial metal then corrodes instead of the protected metal.

Applications:

Zinc Cathodic Anodes are used to protect a wide range of metallic structures in various environments. Common applications are, steel water or fuel pipelines and storage tanks such as home water heaters , steel pier piles as well as boat, ship and submarine hulls along with seawater sides of condensers and other heat exchangers. All Zinc Anodes are available for Government use with full certification as well as for Industrial use.

Forms:

Type ZHS, ZHC, ZSS, ZEP ( STYLE A, B & C ) , ZTS, ZRN with shapes outlined in specification MIL-A-18001. Belmont Metals also offers custom formula, shapes, sizes & straps. Also available are Zinc Replacement Elements and Brass Plugs ( Type ZDT & ZDM ) along with Zinc Pencil Anodes and Brass Plugs.

Read More

Showing all 19 results

Featured products

-

Belmont manufactures style B round anodes for Cathodic Protection of steel hulls & tanks. Available with either 3/8" or 1/2" IPS. The 11" piece has 2 3/4" IPS. Forms: - 2" Diameter x 1" Thick Circle

- 3" Diameter x 1" Thick Circle

- 4" Diameter x 1" Thick Circle

- 5" Diameter x 1" Thick Circle

- 6" Diameter x 1" Thick Circle

- 9" Diameter x 1" Thick Circle

- 11" Diameter x 1" Thick Circle

Belmont Product Code 8001B Nominal Composition: - 99.55% Zn

- Bal

-

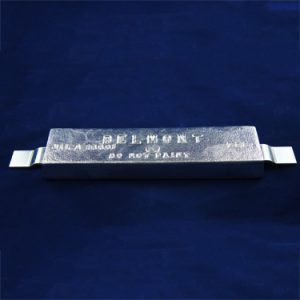

Available for welding or bolt on applications to meet most any requirements for Industrial use or for sale to US Government. Forms: - 1-1/4" x 3" x 12" with 1 Steel Strap approx. 11.5 lbs

- 2 1/2" x 3 1/2" x 12" with 1 Steel Strap approx. 24 lbs

Belmont Product Code 8001ZSS Nominal Composition: - 99.55% Zn

- Bal

-

-

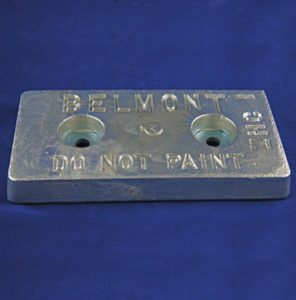

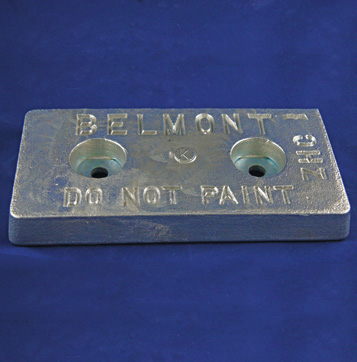

Available for welding or bolt on applications to meet most any requirements for Industrial use or for sale to US Government. Forms: - 1-1/4" x 6" x 12" with Core Strap and 2 Recessed Holes (ZHC-23)

- 2 1/2" x 6" x 12" with Core Strap and 2 Recessed Holes (ZHC-42)

Belmont Product Code 8001ZHC Nominal Composition: - 99.55% Zn

- Bal

-

Anode assembly includes brass retaining plug and replaceable zinc elements. The first element screws into the the one preceding it. Forms: - Plug NPT Sizes: 3/8", 1/2", 3/4", 1"

- Zinc Element options: .500" dia x .750" ht., .625" dia. x .750" ht, .825" dia. x .750" ht., 1.050" dia. x .750" ht

Belmont Product Code 8001ZDM Nominal Composition: - 99.55% Zn

- Bal

-

Our pencil anodes, or engine anodes, are consumed by electrolytic action that would otherwise corrode and harm your equipment. They come with hex brass plugs that vary in in size from 1/4" to 1". Length of the rod varies, from 1" to 24". Forms: - .375" Dia., 3/8-16 NC Thread, 1/4" NPT Plug Size

- .500" Dia., 3/8-16 NC Thread, 3/8"" NPT Plug Size

- .675" Dia., 3/8-16 NC Thread, 1/2" NPT Plug Size

- .750" Dia., 5/8-11 NC Thread, 3/4" NPT Plug Size

- .840" Dia., 1/2" NPT, 1" NPT Plug Size

- Length of the rod varies, from 1" to 24".

Belmont Product Code 8001PEN Nominal Composition: - 99.55% Zn

- Bal

-

-

-

-

-

RELATED POSTS

Engine Zinc Anodes: Protecting Boat Propulsion Systems

Without engines and steering devices, boats cannot move through the water. This vital equipment must work efficiently for recreational and commercial use. However, the metal components used for the engine and as steering for the boat, such as the rudders, outboards, metal struts, stern drives and outboard fittings, can be damaged from the water. Galvanic…

Ship Protection: Zinc Cathodic Anodes Prevents Corrosion

When it comes to materials exposed to water, certain metals will corrode faster than others. This problem is serious for ships that are out in freshwater or saltwater environments. Iron metal is used extensively throughout a ship, from the hull’s body to mechanical equipment, as this material is the most corrosion-prone metal. Other metals also…

Marine Engine Protection: Zinc Rods and Engine Anodes Preventing Corrosion

When thinking about marine operations, whether used in commercial, private or military applications, we typically think about boats and ships traveling long distances across ocean waters. Yet there’s also a range of other structures and equipment that are used in maritime operations. Oil and gas offshore platforms, construction equipment, and materials handling equipment used to…

Keeping Vessels Seaworthy: Common Marine Anode Capabilities

Countless commercial and private operations encounter corrosive environmental elements on a daily basis. Ship vessels, tanks, pipelines, and platforms come in contact with seawater that can erode metal parts such as hulls, rudders, keels, heat exchangers and other components. Disrupting the electrical flow properties of the seawater that creates corrosion is essential to prolong the…

Sacrificial Anodes: Zinc Protecting Parts from Salt Water

Think about a corrosive substance that you deal with in your life. Most people will think about the rust on vehicles caused during the wintertime when road salt mixes with melting snow as it splashes onto the metal parts of their car. Now imagine dealing with saltwater on a daily basis when having maritime jobs…

Powerful protection

Zinc anodes can extend the useful life of metal parts Anyone who has spent time near beaches knows that metal items exposed to saltwater begin to rust quickly. Freshwater encourages oxidation, as well, but because saltwater is a good conductor, electrons move easily through it, accelerating the reactions that cause corrosion. Cathodic protection is one…