Ensure you get the most out of this red-metal alloy by understanding its unique properties With each new generation of electronics, laptops get slimmer and more powerful and cell phones have even greater capacities for the amount of apps, music, and streaming sports and television that consumers want to carry around with them. All these…

|

Con el más alto contenido de cobre de todas las aleaciones de BeCu, esta aleación ofrece una fortaleza y dureza superior, junto con una conductividad térmica superior. Se recomienda para métodos de moldeado centrífugos, continuos y de vaciado. |

|

| Forma |

|

|---|---|

| Código de Producto Belmont | 4992 |

| Composición Nominal |

|

|---|

Productos Relacionados

-

This material offers the highest strength and hardness of all the BeCu alloys with excellent wear resistance and fluidity. Also offers extremely fine detail pick-up in ceramic or pressure cast processes. This also has the lowest pouring temperature of the BeCu alloys allowing almost any type of molding process to be used.

Forma - 1/2" and Down Polished Shot

- 1/2" X 14 Mesh Unpolished Shot

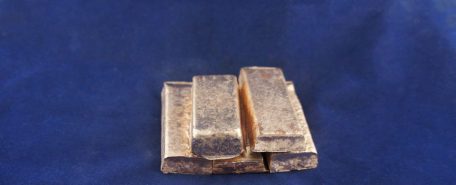

- 2-5 Ingot

Código de Producto Belmont 4971 Composición Nominal - 96.43% Cu

- 2.7% Be

- 0.5% Co

- 0.3% Si

- 0.07% Ti

-

This alloy offers high strength, hardness, wear resistance with excellent fluidity. This alloy is ideal for investment, sand or ceramic casting and provides excellent replication of intricate detail.

Forma - 2-5 Ingot

- 2" Cut Bars

- 1" Cut Bar

- 1/2" Polished Cubes

- 1/2" x 14 Mesh Shot

Código de Producto Belmont 4977 Composición Nominal - 97.2% Cu, 2.05% Be, 0.5% Co, 0.25% Si

-

A Beryllium containing copper base master alloy which is used to introduce Beryllium into new melts or to replace Beryllium lost through oxidation in remelts.

Forma - Approx. 1" Pcs.

- 1/2" and Down Shot

- Slabs

Código de Producto Belmont 4962 Composición Nominal - 96% Cu

- 4% Be

Posteos Relacionados

Bring out the best

Master alloys help copper shine Red metals have played an important role in many cultures, including those of the ancient Egyptians and Romans, who crafted tools, cookware, dishes, mirrors and razors out of copper. Modern uses for copper include electrical, heating/cooling applications, fluid handling and plumbing applications, as well as an increasing demand for the…

Controlling composition using Master Alloys

Create materials that meet specific needs by adding master alloys to the mix It’s important to choose the right materials for a job. Using inferior or unsuitable materials can make completing a project more difficult or even derail it entirely. In the metals industry, combinations of metals, called alloys, are generated to meet the specific…